On 240VAC systems the jumper should be removed. Rated 5060 Hz Enclosure.

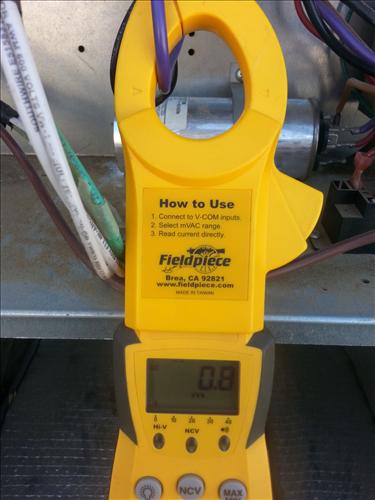

Measure The Amps On A Blower Motor Or Condensing Fan Motor Hvac How To

The branch-circuit short-circuit and ground-fault overcurrent device size.

. The 120-V ac or 240-V ac single-phase power is supplied through the 5-pin connector to the motor at all times even if there is no demand for airflow see Figure 2. This one compares amperage draw of the PSC fan motor to the ECM motor under the same conditions. Its the ECM motor that is more efficient.

460480 volt Breaker Size Motor HP 2 10 20 NA 3 15 30 NA 5 24 48 40 13 26 20 6 12 15. The comparison cannot be shown graphically as the. The motor itself has 3 identical windings somewhat like 3 phase.

-40 C to 55 C -40 F to 130 F Amps. Replace the furnace with one that is equipped with an electronically commutated blower motor. The 5 pins are for power and the 16 pins are for the ECM motors control.

208230 volt Breaker Size Three Phase Full Load Running AMPS. This power is what operates the internal electronics and drives the motor. One is drawing 00226 amps.

208230 volt Three Phase Start Up AMPS. The variable-speed ECM is a dual-voltage motor. The motor has 2 plugs on the control a 16 pin and a 5 pin connection.

The ECM draws a very low current. Totally Enclosed Air Over TEAO. RESCUE ECM Watt Motors Refrigeration Evaporator and Condensing Applications Part Number.

The other DDEC is drawing almost 20 amps. 1550 to 1725 RPM applications Rated Voltages. To interpret the meaning of an amp.

Just like other pumping applications if you can reduce the speed you reduce the pumping head or GPM or both and the results are less amp draw which saves energy. 4 to 25 Watts Speed Range. On the 120VAC systems there should be a jumper between terminals one and two.

It has complete control over the RPM Torque and Amp Draw of the motor which are all variable depending on the application. Electronically Commutated Motors ECMs. The amount of power the motor draws has a rough correlation to the voltage x current amps.

The measured efficiency of an ECM motor is 75-80 at its full rated output. 015 to 075 Hertz. They often draw.

The highest rated motor is the 120V motor at 34 FLC. ECM motors are dual voltage motors capable of operating in 120 or 240VAC systems. The faster electricity is consumed the more heat.

GM once stated that anything over 40 Milliamps draw the battery would need recharged after 3 days of non use. These motors are low starting torque fan motors. 460480 volt Three Phase Start Up AMPS.

It would take this DDEC over a year to draw down a full battery bank. Electricity just like fuel makes heat when its consumed. I last checked a 05 Silverado and after the BCM and other modules went to sleep it had 6 Milliamps of draw.

The other motors in the group phase is the 10-hp 3-phase motor as indicated by the shaded area. The rotor is a permanent magnet. ECM is the initials for Electronically Commutated Motor.

Thus when the voltage gets low the current must increase to provide the same amount of power. Its one of the lesser-used diagnostic tests but perhaps if we focus on how to measure amp draw and learn to better interpret what it can tell us we will expand our ability to provide comfort to those we serve. This video is part of the heating and c.

ECMVariable speed ECMs are much more efficient than conventional blower motors on low speed. I have never had to check a ECM for a current drawIt is always something else drawing. 208230 volt Single Phase Start Up AMPS.

At lower speeds its efficiency stays above 60 even down to 400 rpm at 10 load. 208230 volt Breaker Size Three Phase Full Load Running AMPS. In comparison a typical sleeve bearing induction motor operating at 600 rpm its lowest recommended operating point is as little as 18 efficient.

Or the ampere rating of. When a furnace or air handler with an ECM is installed on a good duct coil and filtration system with static pressures within proper design parameters it can perform flawlesslyIn marginal systems with higher-than-design static pressures the motor still may be able to maintain airflow close to design. Here are two DDECs both being tested with the key off.

Amp draw is a measurement of the power being consumed by a blower motor to move the air through your HVAC system. The NEC does not permit the use of motor nameplate FLA to determine the conductor ampacity. Pump efficiency is not improved by adding an ECM motor to it.

What is an ECM Motor. EC5411E EC5412E EC5414E Horsepower. If the motor is operating at 240VAC with the jumper in place the motor will be permanently damaged.

This reacts with the permanent magnet in the rotor to produce the rotation. Video comparing electrically commutated ECM and permanent split capacitor PSC motors. ECM is the acronym of.

This shortens the ECM battery life. This one compares how many amps the ECM inducer uses compared to a shaded pole inducer on furnaces of similar size. The electronics in the end bell energize the windings one after the other.

This video is part of the heating and cooling series of tra. To drive a fixed mechanical load connected to the shaft a motor must draw a fixed amount of power from the line.

New Wiring Diagram For 40 Amp Relay Diagram Diagramtemplate Diagramsample Check More At Https Servisi Co Wiring Diagra Car Maintenance Car Care Automobile

Measure The Amps On A Blower Motor Or Condensing Fan Motor Hvac How To

Comparison Of Ecm And Psc Blower Motor Amp Draw Youtube

Comparison Of Ecm And Shaded Pole Inducer Amp Draw Youtube

0 comments

Post a Comment